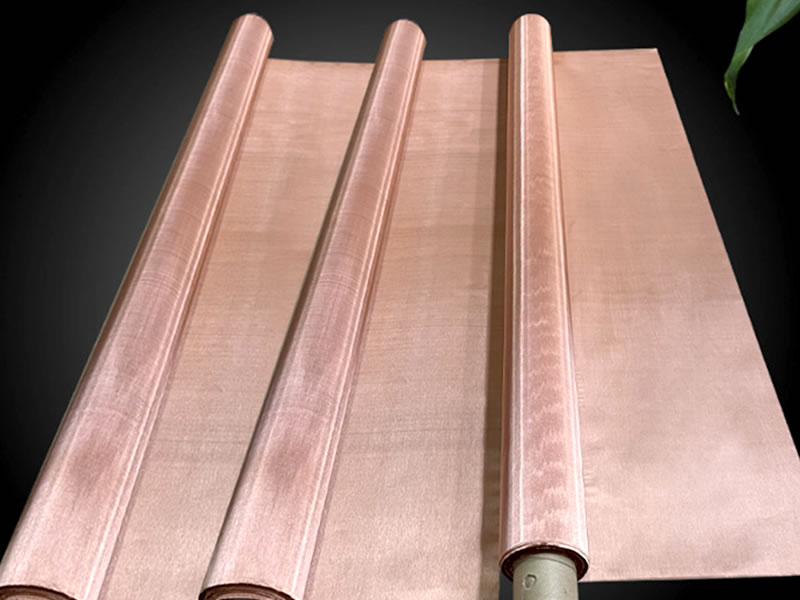

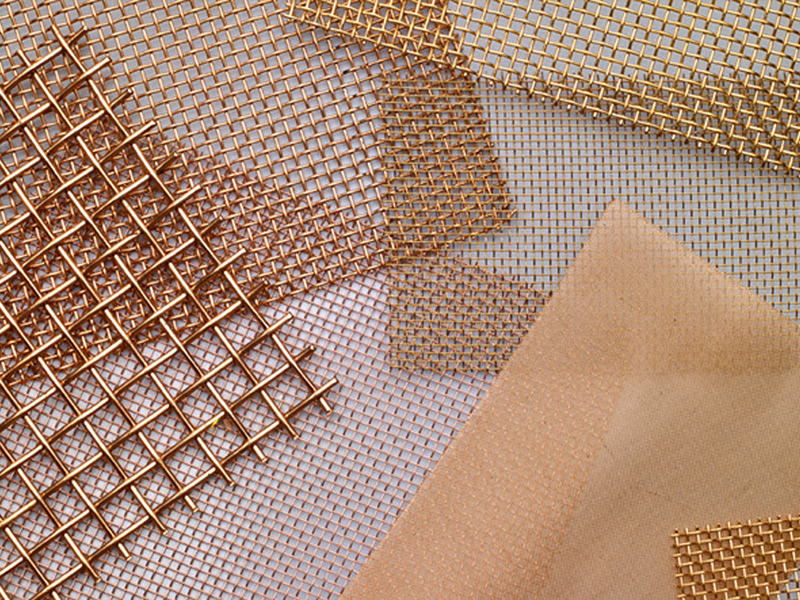

Copper woven wire mesh, also known as shielding screen mesh or “red copper mesh,” is a non-magnetic fabric known for its high electrical and thermal conductivity, wear resistance, and sound insulation. It is often used in circuit boards, laboratories, computer rooms, and various industrial applications requiring effective electromagnetic interference (EMI) and radio frequency interference (RFI) shielding.

Features:

- Electrical Conductivity: Ideal for EMI/RFI shielding, grounding grids, and lightning arrestor elements.

- Thermal Conductivity: Effective for heat dissipation and distribution.

- Non-Magnetic: Suitable for applications where magnetic interference is a concern.

- Corrosion Resistance: Resistant to rust, offering long-term reliability.

- Mesh Count Variability: Available in a wide range of mesh counts from 2 to 300, providing tailored aperture sizes for specific filtration and screening needs.

- Flexibility: Various weave patterns meet diverse structural requirements.

Applications

- RFI/EMI/RF Shielding: Copper wire mesh serves as an effective shield against radio frequency and electromagnetic interference, protecting sensitive electronics and ensuring secure data transmission.

- Faraday Cages: Its high conductivity makes copper mesh ideal for Faraday cages, which block external static and non-static electric fields.

- Electronic Information Security: Copper mesh helps secure electronic information by preventing interference or unauthorized data access.

- Power Generation: Its conductivity makes it useful in power generation applications, including grounding grids and lightning arrestor elements.

- Insect Screens: Copper mesh is highly effective for creating insect screens due to its corrosion resistance and durability.

- Outer Space Exploration and Research: The mesh is used in space technology for shielding sensitive instruments and electronics.

- Fireplace Screens: Its aesthetic appeal, coupled with heat resistance, makes copper mesh ideal for fireplace screens, adding both beauty and safety.

- Residential Projects: Homeowners use copper mesh in gutter guards, soffit screens, and architectural decoration, benefiting from its amber-red color and malleability.

- Artistic and Architectural Applications: Artists and architects utilize copper mesh in sculptures and creative designs, taking advantage of its ductility, rich color, and versatility.

Brass Wire Mesh

Brass wire mesh is a widely used screening material known for its superior abrasion resistance and enhanced corrosion resistance compared to pure copper. It is typically composed of 80% copper and 20% zinc, resulting in a durable alloy that maintains its bright finish over time, unlike copper, which darkens with age. Brass wire mesh offers higher tensile strength than copper but with a slight reduction in formability.

Popular Industries and Applications

- Energy Storage: Brass wire mesh is extensively used in energy storage systems due to its durability and corrosion resistance. It plays a critical role in the structural components of batteries and capacitors.

- Electric Heaters: In electric heaters, brass mesh serves as an effective conductive and heat-resistant element, facilitating efficient heat transfer and distribution.

- Pest Control Fumigation: Utilized in fumigation processes, brass mesh acts as a barrier that ensures secure containment of chemicals while allowing air and fumes to circulate effectively.

- Tactical Shelters & Modular Containers: Brass wire mesh is incorporated into tactical shelters and modular containers for military and emergency use, providing reinforced structural integrity and resistance to environmental factors.

- Robotics & Power Automation: In robotics and power automation, brass mesh contributes to the protection of delicate components and enhances electromagnetic shielding capabilities.

- Gamma Irradiators: Used in the construction of gamma irradiators, brass mesh ensures precise and safe operation by shielding and filtering gamma radiation.

- Health, Body, and Mind Enrichment: Brass mesh finds applications in therapeutic devices and equipment, supporting health and wellness industries through innovative uses that leverage its conductive properties.

- Space Program Initiatives (NASA): NASA utilizes brass wire mesh in various applications within spacecrafts and experimental gear, benefiting from its resistance to space-related corrosive environments and its thermal properties.

- Metalsmithing & Bookbinding: Brass mesh is prized in artistic fields such as metalsmithing and bookbinding for its aesthetic qualities and workability, adding both functionality and decorative value.

- Air & Liquid Filtration and Separation: Due to its fine weave and chemical stability, brass wire mesh is ideal for filtration systems, effectively separating and filtering particulates in both air and liquid applications.

Bronze Wire Mesh

Huansi Wire Mesh Products Co., Ltd. provides bronze wire mesh products in a range of types and specifications, tailored to cover a broad spectrum of applications.

Bronze wire mesh, particularly phosphor bronze, consists of a composition of copper (94%), tin (4.75%), and phosphorus (0.25%). This alloy combines the strength and durability of copper with the corrosion resistance and ductility of tin, enhanced further by the phosphorus. These characteristics make phosphor bronze wire mesh exceptionally resilient and corrosion-resistant, with physical properties that outperform standard copper and zinc alloys.

Typically produced in finer meshes, such as 100 x 100 or finer, phosphor bronze wire mesh offers excellent strength while maintaining fine filtration capabilities. Its anti-corrosive properties make it ideal for applications that require durability in harsh environments. The material is also valued for its high electrical conductivity and wear resistance, providing reliable performance across various industrial, commercial, and architectural applications.

Materials

Phosphor bronze wire mesh, a strong and corrosion-resistant material, is created from an alloy that primarily includes copper, tin, zinc, and phosphorus. The composition varies across three key grades:

- C51000 (CuSn4) Phosphor Bronze:

Composition: 94% copper, 4% tin, and 0.25% phosphorus.

Characteristics: Offers remarkable flexibility, ductility, and fatigue resistance.

Applications: Ideal for applications requiring a balance of strength and ductility. - C51900 (CuSn6) Phosphor Bronze:

Composition: 93% copper and 6% tin.

Characteristics: Provides improved strength and enhanced wear resistance due to a higher tin content.

Applications: Suited for mechanical applications that demand greater strength. - C52100 (CuSn8) Phosphor Bronze:

Composition: 92% copper and 8% tin.

Characteristics: The highest tin content offers superior mechanical strength, ductility, and corrosion resistance.

Applications: Suitable for critical industrial uses requiring robust mechanical properties and resilience.

Part specs of bronze wire mesh

| Mesh/In | Wire Dia.(In) | Opening(In) | Open Area(%) | Weave Type | Width |

| 2 | 0.063 | 0.437 | 76 | PSW | 36″ |

| 4 | 0.047 | 0.203 | 65 | PSW | 40″ |

| 8 | 0.028 | 0.097 | 60 | PSW | 36″ |

| 16 | 0.018 | 0.044 | 50 | PSW | 36″ |

| 18 X 14 | 0.011 | 0.044 X 0.06 | 67 | PW | 48″ |

| 18 X 14 | 0.011 | 0.044 X 0.06 | 67 | PW | 60″ |

| 20 | 0.016 | 0.034 | 46 | PSW | 36″ |

| 30 | 0.012 | 0.021 | 40 | PSW | 40″ |

| 40 | 0.01 | 0.015 | 36 | PSW | 36″ |

| 50 | 0.009 | 0.011 | 30 | PSW | 36″ |

| 100 | 0.0045 | 0.0055 | 30 | PSW | 40″ |

| 150 | 0.0026 | 0.004 | 37 | PSW | 36″ |

| 200 | 0.0021 | 0.0029 | 33 | PSW | 36″ |

| 250 | 0.0016 | 0.0024 | 36 | PSW | 40″ |

| 325 | 0.0014 | 0.0016 | 29 | TSW | 36″ |

| 400 | 0.00098 | 0.00152 | 36 | PSW | 39.4″ |

| Type | Red Copper Wire Mesh | Brass Wire Mesh | Phosphor Bronze Wire Mesh | Tinned Copper Wire Mesh |

| Materials | 99.99% pure copper wire | H65 wire (65%Cu-35%Zn ) H80 wire (80%Cu-20%Zn ) | Tin bronze wire | Tinned copper wire |

| Mesh Count | 2-300 mesh | 2-250 mesh | 2-500 mesh | 2-100 mesh |

| Weave Type | Plain/Twill Weave and Dutch Weave | |||

| Common Size | Width 0.03m-3m; Length 30m/roll, Can also be customized. | |||

| Common Feature | Nonmagnetic, good ductility , Wear resistance, Fast heat transfer, Good electrical conductivity | |||

| Special Features | Sound insulation Electron filtration | Maintain its bright finish over time | Great strength, durability and ductility | High temperature resistance, anti-aging,and long service life |

| Common Applications | EMI/RFI shielding Faraday cage | Apply to Newspaper/Typing/chinaware printing; Smoking screen; | Apply to Chinaware printing, screening all kinds of particles,powders and porcelain clay | Engine filter for cars, Noise reduction, damping(suspension ) |