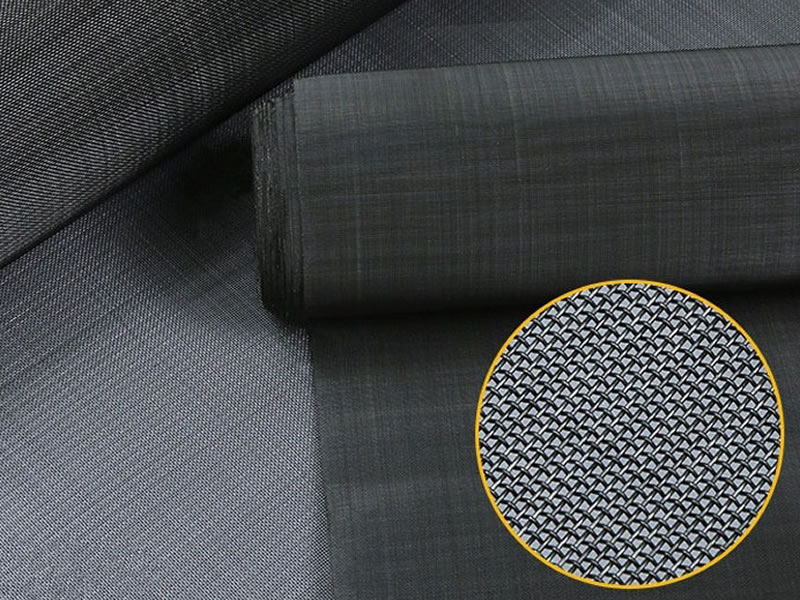

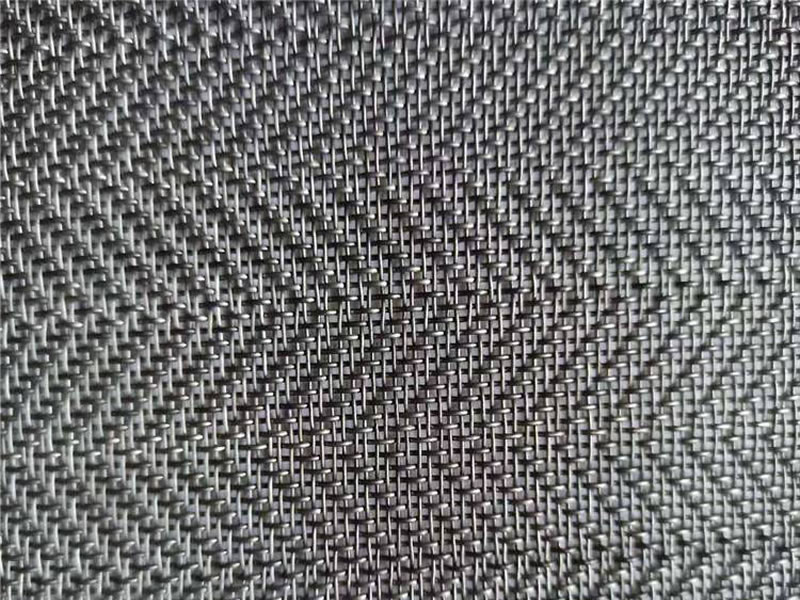

Black wire cloth, also known as plain steel wire cloth, is a versatile filtration material offering consistent mesh patterns and a smooth surface. It is manufactured using black iron wire in two weaving patterns: plain woven and dutch woven. This durable cloth is highly effective for filtering gases and liquids across various industries.

Materials

- Bright Pure Tungsten Wire: Known for its resistance to high temperatures and corrosion.

- Black Pure Tungsten Wire: Offers similar properties to bright tungsten with additional oxidation resistance.

- Annealed Low Carbon Steel Wire: A cost-effective option with good strength.

- Galvanized Steel Wire: Adds rust protection for outdoor or moisture-prone environments.

- Brass or Copper Wire: Provides corrosion and oxidation resistance.

Mesh Count

- Low Mesh Count (0.3-10):

Suitable for coarse filtering and separation processes, commonly used in applications requiring large particle separation or screening. - Medium Mesh Count (10-100):

Ideal for applications requiring finer filtration, such as oil or chemical industries, providing moderate filtration precision. - High Mesh Count (100-400):

Designed for fine filtration, typically used in critical filtration systems for the pharmaceutical, rubber, and food industries where precision is essential.

This versatility in mesh count range allows for optimal selection based on specific filtration needs, providing solutions across industries with varying levels of filtration requirements.

Weaving Types

Plain Weave:

- Structure: Simple one-over-one-under pattern.

- Applications: Best for applications requiring uniform apertures, such as general filtering or protective covers.

- Mesh Sizes: Available in a wide range of mesh sizes, typically from 0.3 to 400 mesh.

Twill Weave:

- Structure: Each wire passes over two or more wires, creating a diagonal pattern.

- Applications: Suitable for finer filtration, where enhanced strength and tighter mesh are necessary.

- Mesh Sizes: Usually woven between 20 to 400 mesh.

Dutch Weave:

- Structure: Denser weave with a combination of finer weft and coarser warp wires.

- Applications: Ideal for precise filtration tasks, especially in the oil and gas, chemical, and food industries.

- Mesh Sizes: Typically ranges from 10 to 400 mesh.

These weaving types allow for tailored solutions to various filtration and screening challenges, ensuring compatibility with different industries and processes.

| Black Wire Cloth – Plain/Twilled weave | ||

| Mesh/Inch | Wire Diameter | Aperture |

| 8mesh x 8mesh | 0.71mm | 2.47mm |

| 10mesh x 10mesh | 0.60mm | 1.94mm |

| 12mesh x 12mesh | 0.60mm | 1.52mm |

| 14mesh x 14mesh | 0.50mm | 1.31mm |

| 16mesh x 16mesh | 0.60mm | 0.988mm |

| 20mesh x 20mesh | 0.50mm | 0.77mm |

| 20mesh x 20mesh | 0.40mm | 0.87mm |

| 30mesh x 30mesh | 0.30mm | 0.55mm |

| 30mesh x 30mesh | 0.25mm | 0.59mm |

| 40mesh x 40mesh | 0.21mm | 0.43mm |

| 50mesh x 50mesh | 0.17mm | 0.34mm |

| 60mesh x 60mesh | 0.15mm | 0.28mm |

| 60mesh x 60mesh | 0.17mm | 0.25mm |

| 70mesh x 70mesh | 0.14mm | 0.24mm |

| 80mesh x 80mesh | 0.14mm | 0.18mm |

| 100mesh x 90mesh | 0.11mm | 0.15mm |

| Black Wire Cloth – Dutch Weave | |

| Mesh/Inch | Wire Diameter |

| 12mesh x 64mesh | 0.60mm x 0.40mm |

| 14mesh x 88mesh | 0.50mm x 0.33mm |

| 24mesh x 110mesh | 0.36mm x 0.25mm |

| 30mesh x 150mesh | 0.24mm x 0.18mm |

| 40mesh x 200mesh | 0.18mm x 0.13mm |

| Black Wire Cloth – Herringbone style | |

| Mesh/Inch | Wire Diameter |

| 30mesh | 0.45mm |

| 40mesh | 0.35mm |

| 36mesh | 0.35mm |

| 30x24mesh | 0.45mm |