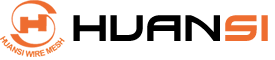

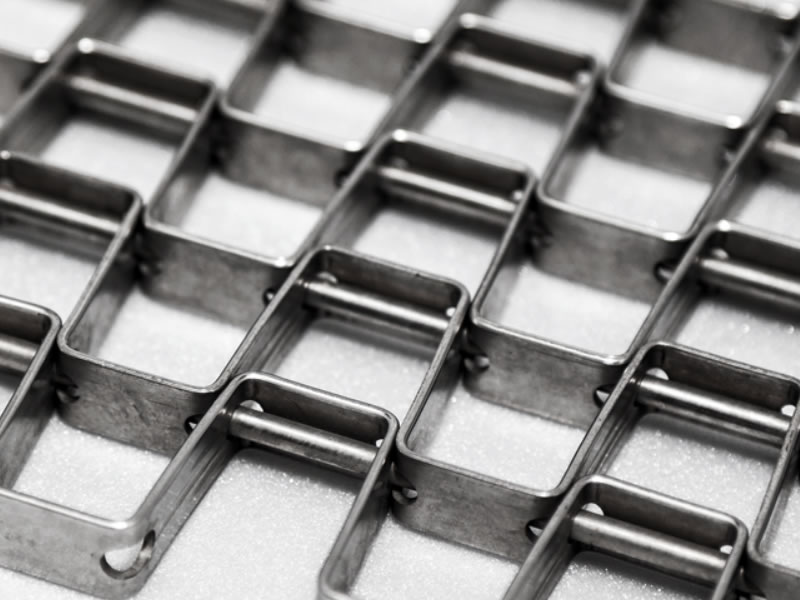

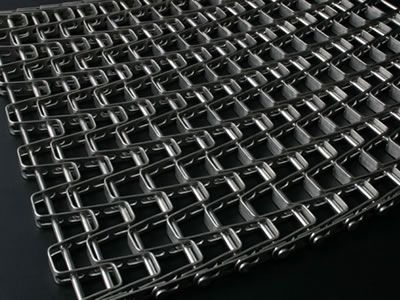

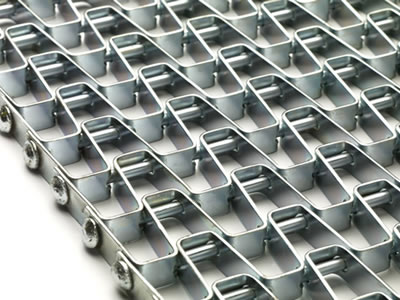

Our Flat Wire Conveyor Belts are designed for exceptional durability and strength, catering to the diverse needs of industrial operations. These belts feature flat strip belting linked by straight rods, creating a robust open weave that enhances air flow and drainage. This design simplifies cleaning and maintains optimal functionality under various conditions.

Available in different materials, our belts can be tailored with openings in sizes such as 1/2×1/2, 1/2×1, and 1×1. Clients can select from standard or heavy-duty options, with clinched or welded selvage to suit specific applications.

Ideal for a broad range of uses including fertilizer transport, food breading, and more demanding processes like cleaning, drying, and freezing, these belts also support packaging, baking, and transfer tasks in conveyor systems. We also offer compatible sprockets that ensure precise and reliable operation, facilitating seamless integration and sustained performance in challenging industrial settings.

Materials

Flat Wire Conveyor Belts are crafted from several durable materials suited for various industrial applications:

- Carbon Steel: Strong and cost-effective, ideal for applications where high durability is needed. It’s less resistant to corrosion, so it may require protective coatings in certain environments.

- SS304 Stainless Steel: Known for excellent corrosion resistance, SS304 is ideal for food processing and pharmaceutical industries where cleanliness and resistance to oxidation are crucial.

- SS316 Stainless Steel: Offers enhanced corrosion resistance due to higher nickel content and the addition of molybdenum. SS316 is perfect for harsher environments, including marine and chemical processing applications.

These materials ensure that each conveyor belt can perform under different industrial conditions, providing reliability and longevity in various operational settings.

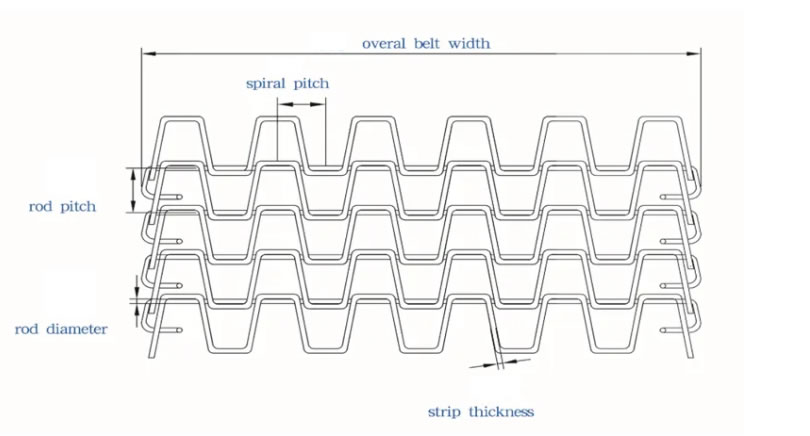

Specifications

Flat Wire Conveyor Belts come with detailed, customizable specifications to meet diverse industrial needs:

- Spiral Pitch: Ranges from 15 mm to 30 mm, influencing the belt’s flexibility and product handling capacity.

- Pitch: Available from 12.7 mm to 76.2 mm, allowing adjustment based on material size and spacing requirements.

- Rod Diameter: Varies between 2 mm and 12 mm to accommodate different strengths and load capacities.

- Plate Thickness: Between 0.8 mm and 3 mm, selected based on the required durability and strength for specific applications.

- Plate Width: From 8 mm to 25 mm, affecting the conveyor’s surface area and material stability.

- Overall Width: Extends from 100 mm to 6000 mm, suitable for various application scales, from compact to extensive.

- Special Specifications: Custom options are available to ensure each belt is ideally suited for its specific application.

These specifications ensure that each conveyor belt can be tailored for optimal performance in any industrial setting.

Usage

Flat Wire Conveyor Belts are versatile and suitable for various industrial applications due to their robust design:

- Cooling and Drying: Ideal for processes that require good air circulation, these belts help in efficiently cooling and drying products by enhancing airflow.

- Bread Production: Used extensively in the baking industry, these belts are integral to both the proofing and cooling stages of bread production, ensuring even heat distribution and effective cooling.

- Washing: Their durable structure makes these belts perfect for washing systems, particularly in food processing, allowing water and debris to drain away effectively.

- Sorting Systems: These belts are also used in sorting facilities to transport and organize items efficiently, supporting operations without compromising product integrity.