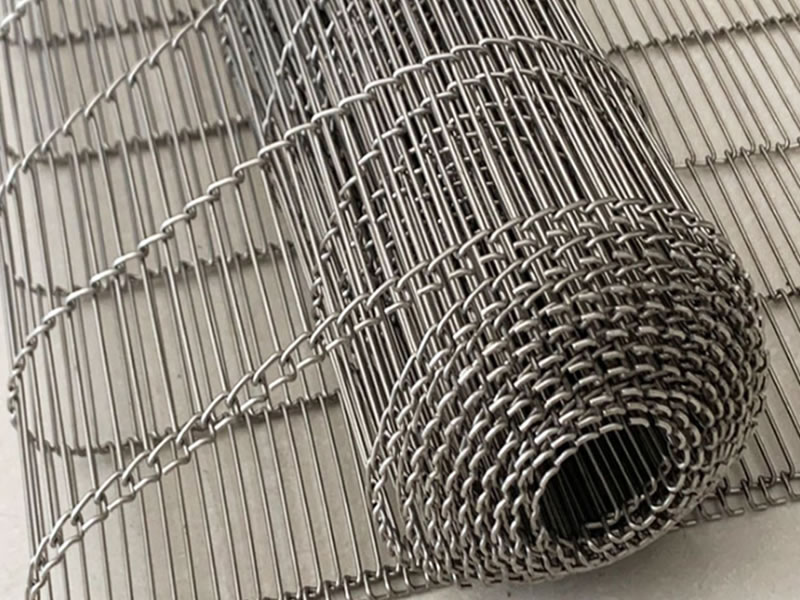

Flat Flex Conveyor Belts are gear-driven belts known for their good ventilation and consistent tension, offering high-temperature resistance, pressure tolerance, corrosion resistance, and a long operational lifespan. Their flexible rotation and stability make them ideal for various applications.

These belts typically have a single-layer structure, making them lightweight and easy to maneuver. They are driven by sprockets and feature a large open area (70-85%), providing ample airflow. This makes them suitable for lighter product cooling, frying, baking, drying, heating, decoration, coating, and packaging equipment. They deliver reliable performance across different applications, ensuring efficient production and handling.

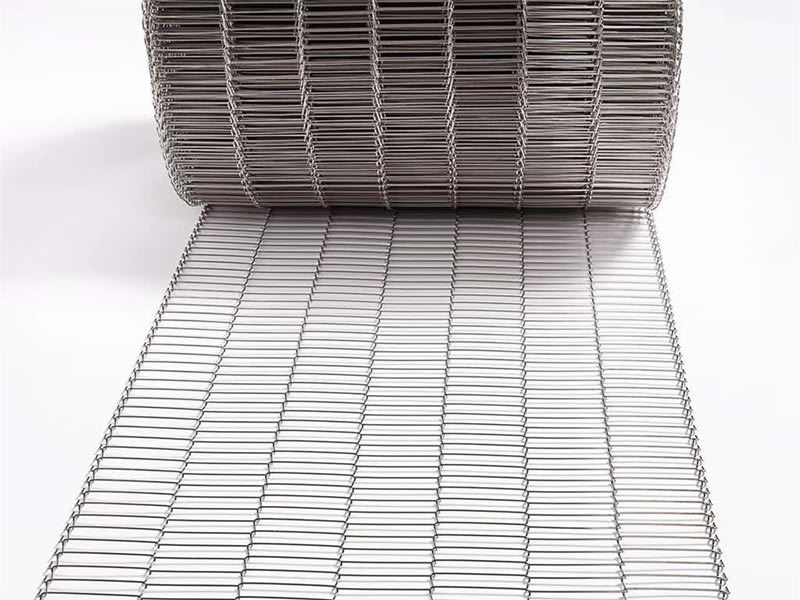

Specifications

- Material

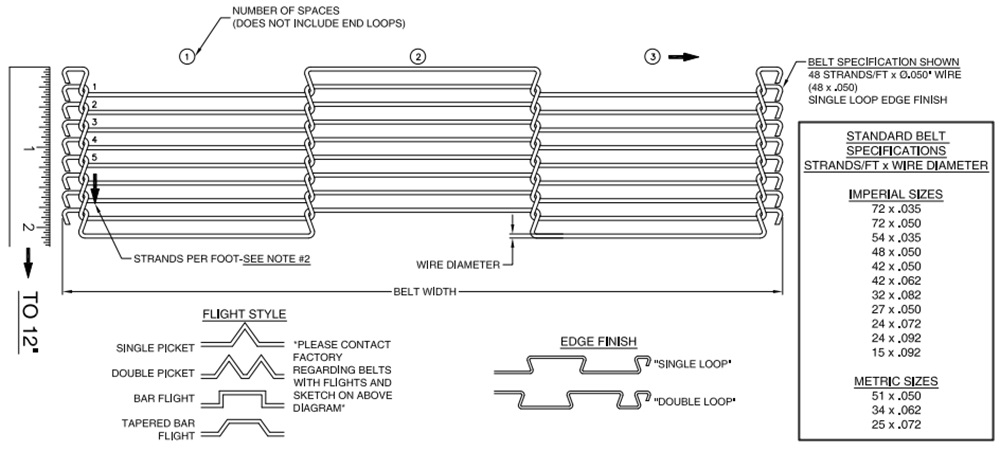

Flat Flex Conveyor Belts are commonly manufactured using stainless steel grades like SS304, SS316, and SS316L. These grades offer high resistance to corrosion, pressure, and temperature, ensuring reliable performance in demanding environments. - Pitch (mm)

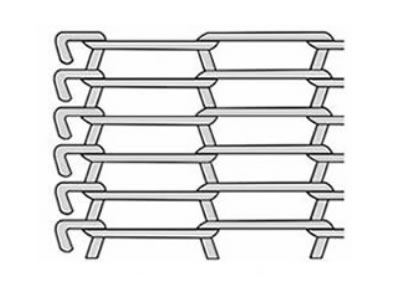

The pitch, which is the spacing between adjacent wires or links, ranges from 4 to 20 mm. This flexibility allows for varied applications, providing efficient product flow. - Wire Diameter (mm)

Wire diameters range from 1 to 3 mm, striking a balance between strength and flexibility for diverse applications. This range offers the appropriate blend of durability and lightweight construction. - Overall Width (mm)

With an overall width between 100 and 3000 mm, these belts can be customized to match specific production needs and equipment dimensions. - Sprocket Compatibility

Designed to work with sprockets, these belts can be supplied with sprockets that vary in keyway, keyway depth, bore diameter, and overall diameter. This ensures smooth, accurate belt operation. - Special Specifications

Custom specifications can be tailored to accommodate unique industrial requirements.

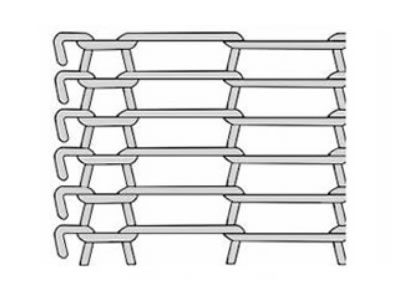

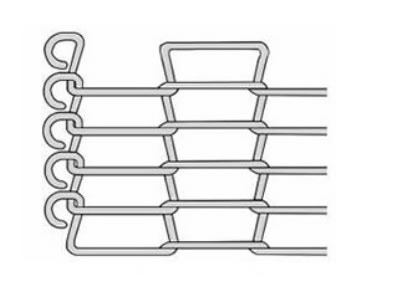

Flat Flex Wire Mesh Belt Edges

The flat flex conveyor belt can be formed into different edge types, which can suit different equipment and driven types. You can choose the perfect one suit for you.

Flat Flex Wire Mesh Belt Drawing

Features

- Smooth Surface: Ensures efficient movement of products and minimizes damage.

- Various Shapes: Adaptable to different designs and production lines.

- Long Lifespan: Made from high-grade stainless steel, offering long-term usage.

- High Strength: Strong enough to handle heavy loads while resisting deformation.

- Rust & Corrosion Resistance: Stainless steel construction provides strong resistance to rust and corrosion, suitable for harsh environments.

- Heat & Erosion Resistance: Performs well under high temperatures and resists erosion.

- Flexible Capability: Offers smooth movement around sprockets and pulleys.

- Enduring Quality: Maintains stability and structural integrity over prolonged use.

- High Permeability: Allows air and liquids to pass through, making it suitable for drying, heating, or cooling applications.

- Shape Retention: Maintains its form under various conditions without deforming easily.

Applications

Food Processing Industry:

- Cooling & Frying: The belt’s open structure and high permeability ensure efficient airflow and heat exchange, making it ideal for cooling and frying processes.

- Baking & Drying: Used in baking ovens and drying tunnels for uniform heat distribution.

- Decorating & Packaging: Suitable for coating, decorating, and packaging food products due to its smooth surface and stability.

Automotive & Manufacturing Industry:

- Assembly Lines: Efficient in transporting small automotive parts and components across various stages of the assembly line.

- Heat Treatment: Withstands high temperatures for processes like heat treatment and annealing.

Pharmaceutical & Chemical Industry:

- Drying & Heating: Ideal for handling sensitive chemical or pharmaceutical products, allowing controlled drying and heating with minimal contamination.

- Sorting & Transporting: Safely transports chemicals in various states due to its corrosion resistance.

Textile Industry:

- Dyeing & Washing: The corrosion-resistant and open mesh design makes it suitable for dyeing and washing textiles.

- Finishing Processes: Effective in drying and finishing fabric, providing uniform air and liquid flow.

Electronics Industry:

- Circuit Board Manufacturing: The belt’s fine mesh allows for secure transport of delicate circuit boards.

- Component Coating & Testing: Provides stable and reliable handling during coating and testing of electronic components.