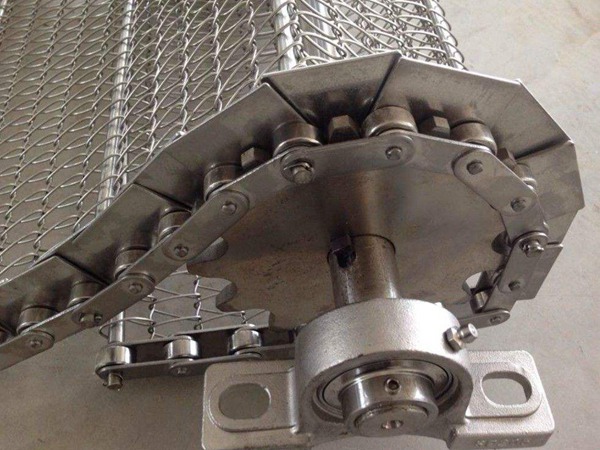

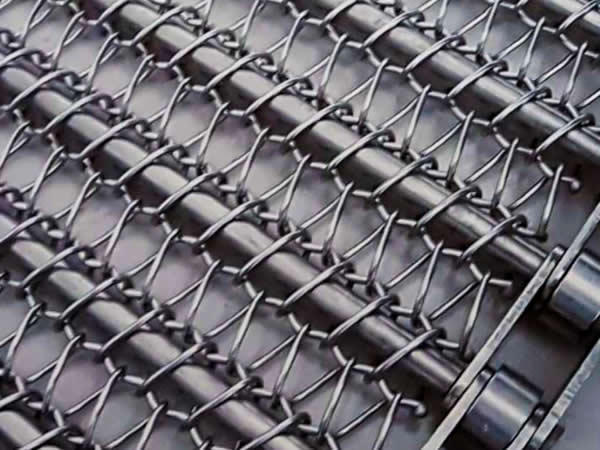

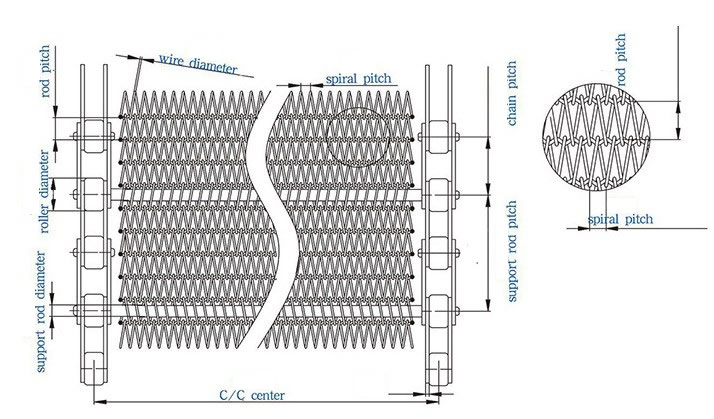

Chain driven conveyor belts are powered by cross rods that connect chain strands by passing through or underneath the wire mesh fabric. The density of the wire mesh fabric is selected based on the size of the products conveyed. This ensures optimal transport and stability of the items on the belt. Chain driven belts offer smooth operation and reliable performance, making them suitable for various industrial applications where efficient and steady material movement is essential. They are available in different types and specifications to meet the diverse needs of conveyor systems across multiple industries.

Specifications:

Material

- Carbon Steel:Durable and cost-effective for general applications.

- SS 201:Moderate corrosion resistance, suitable for light-duty processing.

- SS 304:Highly corrosion-resistant, ideal for high-moisture environments.

- SS 316:Maximum corrosion resistance, great for chemical and marine use.

Spiral Pitch

- 6 mm: The smallest pitch size, offering a tight weave. Ideal for transporting small or delicate items, ensuring maximum stability.

- 8 mm to 15 mm: These options provide slightly wider spacing while maintaining excellent stability. Suitable for conveying products that require a closely-knit structure.

- 16 mm to 25 mm: Offers a good balance between open area and support. These pitches are versatile, ideal for drying, cooling, or heating medium-sized products.

- 26 mm to 40 mm: The widest range of spiral pitches available. Best suited for conveying larger items or those requiring substantial airflow or liquid drainage during processing.

Wire Diameter

- 1.2 mm: Suitable for handling lightweight items that require delicate transport.

- 1.4 mm: Provides slightly more stability for small, light-duty products.

- 1.5 mm: Balances strength and flexibility for moderate-weight products.

- 1.6 mm: Offers enhanced strength, ideal for medium-sized items.

- 1.8 mm: Adds durability while maintaining flexibility, useful for medium-duty loads.

- 2 mm: A robust option for moderately heavy products, providing stability and longevity.

- 2.5 mm: Delivers significant durability and load-bearing capacity, perfect for heavy-duty applications.

- 3 mm: The strongest diameter available, ideal for handling the heaviest loads with maximum durability.

Rod Pitch

- 5 mm to 10 mm: Narrow rod pitches offer close support for small items, preventing slippage. They are ideal for products that require precise placement and careful transport.

- 11 mm to 20 mm: These pitches provide a balance between stability and openness. Medium pitches are versatile for a variety of applications where both airflow and product support are essential, such as in cooling and drying.

- 21 mm to 30 mm: Wider rod pitches offer significant space between rods. These are suitable for larger items that require more open spacing to facilitate drainage or to handle products that can be safely conveyed on larger gaps.

Belt Width

- 200 mm to 1,000 mm: Narrow belt widths are perfect for small conveyor systems handling compact items. They provide precise control for applications like food processing and small parts manufacturing.

- 1,001 mm to 2,500 mm: Medium-sized belts offer a versatile solution, balancing capacity and adaptability for conveyor systems. They are suitable for various industries where medium-scale production or processing is required.

- 2,501 mm to 5,000 mm: Wide belts cater to large-scale production lines, offering extensive capacity for transporting bulk goods or processing large products. They ensure consistent and efficient movement of items across extensive widths.

Characteristics

- Positive Drive: The cross rods provide a positive and secure drive mechanism, preventing slippage and ensuring smooth operation.

- Smooth Running: The belt’s design ensures uniform and steady movement, reducing friction and vibration during conveying.

- Minimal Pressure on Mesh Fabric: The distribution of the cross rods and chains applies minimal pressure on the wire mesh fabric, prolonging the belt’s lifespan.

- Wide Temperature Range: With an operating range from -55°C to 1150°C, these belts can handle extreme temperatures, making them suitable for both freezing and high-temperature processes.

- Side Guards and Flights Available: Side guards can be added for product containment, while flights are used for carrying products at various incline angles, improving versatility in handling different materials.

Applications

- Cooling

Chain-driven conveyor belts effectively cool products transitioning quickly from high to low temperatures. Their open structure ensures sufficient airflow or liquid exposure for heat dissipation in cast metals, food items, and manufactured components. - Drying

Their mesh design aids in moisture removal by promoting airflow, supporting the drying of textiles, food, and industrial components, often with the help of fans or heaters. - Lift Guards

In lift systems, these belts act as guards, preventing items from falling off during transport while providing secure containment and easy maintenance. - Heating

The heat-resistant construction makes these belts ideal for high-temperature applications above 200°C, crucial for baking, annealing, or curing ceramics, glass, and food products. - Transporting Light-Duty Products

They offer stable surfaces for transporting lightweight items like packaging materials and delicate foods. - Industrial Curtains

In industrial settings, these belts can serve as protective curtains, safeguarding workers from heat, sparks, and hazards while maintaining visibility and airflow.