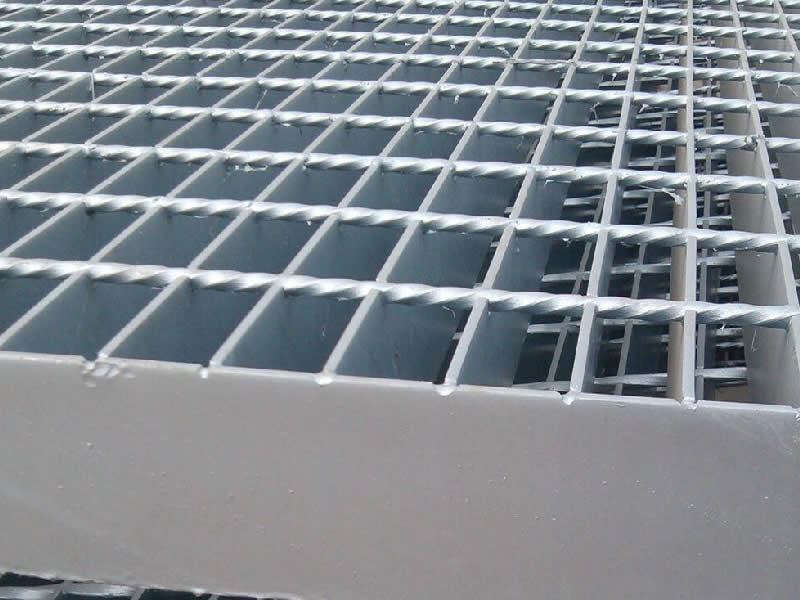

Steel grating is a robust structure made from steel bars welded or locked together at junctions, forming a grid-like pattern.The main components of steel grating include bearing bars, which are vertically positioned at regular intervals to carry loads, and cross bars, which are horizontally fixed to stabilize the structure. There are two main manufacturing processes: Welded Steel Grating, where bars are welded at intersections for stability and durability, and Pressure-Locked Grating, where bars are mechanically locked without welding under high pressure.

Materials of Steel Bar Grating

- Carbon Steel Grating: Widely used for its strength and cost-effectiveness, often galvanized to resist corrosion.

- Stainless Steel Grating: Offers excellent corrosion resistance and is ideal for harsh chemical or sanitary environments.

- Aluminum Grating: Lightweight and corrosion-resistant, suitable for marine and architectural applications.

- Galvanized Steel Grating: Carbon steel coated with zinc to enhance durability and corrosion resistance.

- Fiberglass Grating: Non-metallic option that is lightweight, non-conductive, and resistant to chemicals.

Bearing Bar Types of Steel Grating

Steel grating is available in various bearing bar types, each designed to meet specific needs in different environments:

Smooth Flat Steel Bar Grating

- Features: Flat, even surface.

- Applications: Ideal for stable movement in areas such as walkways and equipment pathways.

Serrated Toothed Bar Steel Grating

- Features: Equipped with a serrated, tooth-like pattern.

- Applications: Provides enhanced slip resistance, suitable for wet or oily environments.

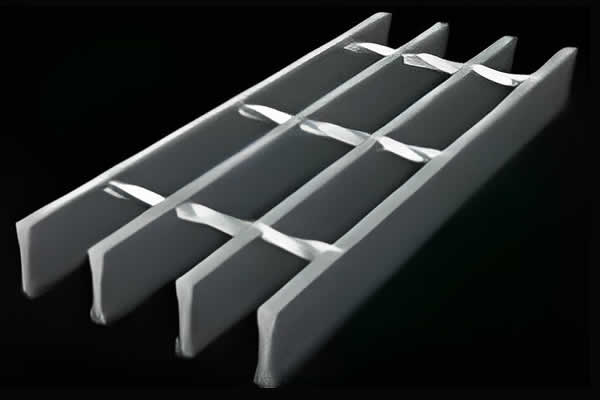

Smooth I Bar Steel Grating

- Features: Characterized by an I-shaped cross-section.

- Applications: Used where load-bearing capacity and material efficiency are critical, offering reduced weight and high strength.

Serrated I Bar Steel Grating

- Features: I-shaped profile with a serrated surface.

- Applications: Delivers structural efficiency and slip resistance, ideal for areas requiring strength and safety in challenging conditions.

Specification

Steel grating is a robust material widely used in architectural and industrial applications. Choosing the correct dimensions and spacing of the bars is crucial for optimal performance and safety.

Bearing Bar Pitches

Bearing bar pitches, the distance between the centers of the individual bearing bars, significantly influence the grating’s load capacity and support. Common pitches include:

- 15mm: Ideal for preventing small objects from passing through.

- 22mm and 25mm: Used in areas requiring moderate load-bearing.

- 30mm: Common in industrial settings for a balance of strength and openness.

- 32.5mm and 34mm: Provide more open space, beneficial for enhanced drainage or airflow.

- 40mm: Excellent for pedestrian areas or decorative uses due to great air and light flow.

- 50mm to 90mm: Suitable for heavy-load applications or where maximum material and water flow-through is needed.

The most effective pitches for balancing strength, durability, and cost are 25mm, 30mm, 34mm, and 40mm.

Crossbar Pitches

Crossbar pitches, the space between the crossbars connecting the bearing bars, affect the grating’s weight and material passage capabilities. Ranges and preferred sizes include:

- 24mm to 200mm: Covers a broad spectrum of functional and aesthetic needs.

- 50mm: Common in standard industrial applications.

- 76mm: Selected for specialized uses requiring larger openings and lighter weight.

- 100mm: Optimal for maximum space for passage, suitable for water features or heavy debris areas.

Selecting suitable bearing bar and crossbar pitches is essential for steel grating to meet specific environmental demands. Pitches of 25mm, 30mm, 34mm, and 40mm for bearing bars, combined with crossbar pitches of 50mm, 76mm, and 100mm, provide adaptable solutions for various structural requirements, effectively balancing open area, strength, and material flow.

Steel Grating Introduction

| Bearing Bar Type | Flat Bar | I Bar | Serrated Bar |

| Cross Bar Type | Twisted Bar | Round Bar | Flat Bar |

| Production Process | Welded | Pressure Locked | |

| Surface Treatment | Self-Colour | Galvanized | Painted |

| Application | Platform | Walkway&Floor | Trench Cover |

| Suspended Ceiling | Barrier Fence | Steel Stair Treads |

Steel Grating Specification

Panel size available(black grating): 1000x5800mm or 1000x6000mm

| Bearing Bar Pitch | Cross Bar Pitch | Bearing BarSize (Width ×Thickness) | |||||

| 20×3 | 25×3 | 32×3 | 40×3 | 20×5 | 25×5 | ||

| 30 | 100 | G203/30/100 | G253/30/100 | G323/30/100 | G403/30/100 | G205/30/100 | G255/30/100 |

| 50 | G203/30/50 | G253/30/50 | G323/30/50 | G403/30/50 | G205/30/50 | G255/30/50 | |

| 40 | 100 | G203/40/100 | G253/40/100 | G323/40/100 | G403/40/100 | G205/40/100 | G255/40/100 |

| 50 | G203/40/50 | G253/40/50 | G323/40/50 | G403/40/50 | G205/40/50 | G255/40/50 | |

| 60 | 50 | G203/60/50 | G253/60/50 | G253/60/50 | G403/60/50 | G205/60/50 | G255/60/50 |

| Bearing Bar Bitch | Cross Bar Pitch | Bearing BarSize (Width ×Thickness) | |||||

| 32×5 | 40×5 | 45×5 | 50×5 | 55×5 | 60×5 | ||

| 30 | 100 | G325/30/100 | G405/30/100 | G455/30/100 | G505/30/100 | G555/30/100 | G605/30/100 |

| 50 | G325/30/50 | G405/30/50 | G455/30/50 | G505/30/50 | G555/30/50 | G605/30/50 | |

| 40 | 100 | G325/40/100 | G405/40/100 | G455/40/100 | G505/40/100 | G555/40/100 | G605/40/100 |

| 50 | G325/40/50 | G405/40/50 | G455/40/50 | G505/40/50 | G555/40/50 | G605/40/50 | |

| 60 | 50 | G325/60/50 | G405/60/50 | G455/60/50 | G505/60/50 | G555/60/50 | G605/60/50 |

Steel Grating Standard

| Steel Grating Standard | |||

| Steel Grating Standard | Steel Standard | Galvanizing Standard | |

| China Standard | YB/T 4001.1-2007 | GB700-88 | GB/T13912-2002 |

| USA Standard | ANSI/NAAMM (MBG531) | ASTM (A36) | ASTM (A123) |

| U.K. Standard | BS4592 | BS4360 (43A) | BS729 |

| Australia Standard | AS1657 | AS3679 | AS1650 |

| GermanyStandard | DIN24537 | DIN17100-80 | DIN50976 |

Applications of Steel Grating

Steel grating is utilized in various settings for its strength and versatility. Here are some specific applications:

Industrial and Infrastructure

- Flooring and Walkways: Used for industrial floors, walkways, and ramps, valued for its durability and safety.

- Maintenance Platforms: Provides stable platforms in factory and workshop maintenance areas.

- Drain and Manhole Covers: Ideal for drain and manhole covers due to its load-bearing capacity and water permeability.

- Trench and Water Channel Grating: Crucial for managing water flow in civil and agricultural settings.

Commercial and Architectural

- Stair Treads and Mezzanines: Ensures safety and stability in commercial buildings, suitable for staircases and mezzanine floors.

- Balustrades and Facades: Employed as infill for balustrades and in creating architectural facades.

- Sun Screens: Offers shading and allows ventilation, commonly used on building exteriors.

Transport and Public Venues

- Bus Stations and Airports: Used in flooring and barriers for crowd management and safety.

- Port Platforms: Provides durable flooring in ports and docks, capable of supporting heavy loads and resisting marine conditions.

Residential and Safety Barriers

- Fences and Balconies: Used in residential areas for balcony railings and yard fences, providing security and aesthetic appeal.

- Safety Barriers: Employed in agricultural and civil settings as fencing to protect and delineate spaces effectively.