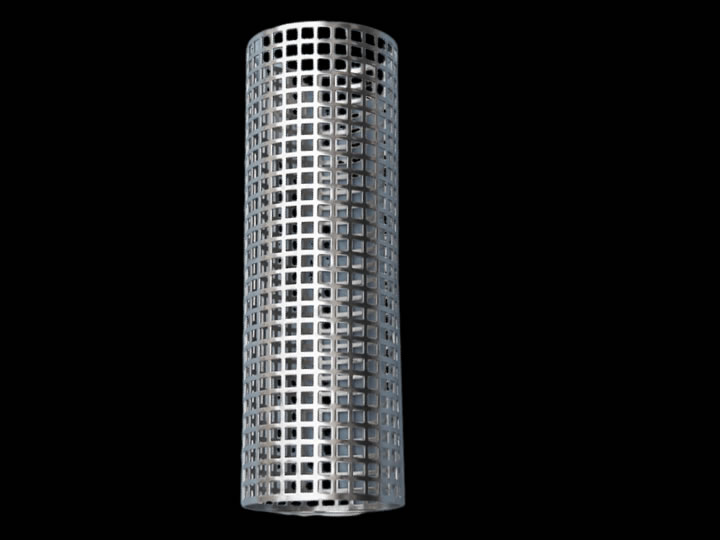

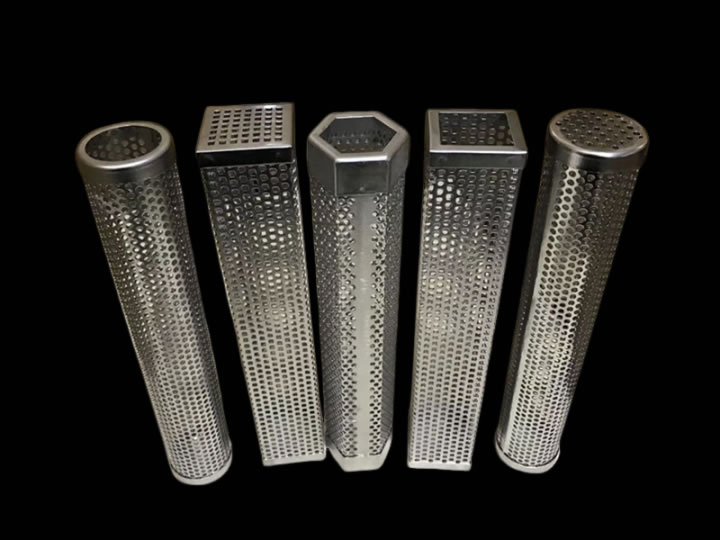

We offer a broad range of perforated metal tubes, primarily focusing on Stainless Steel Perforated Tubes designed for pleated filters. These tubes provide essential mechanical and structural support, enhancing the strength and extending the lifespan of filter elements. Available in a variety of hole patterns including round, rectangular, square, triangle, diamond, hexagonal, cross, and slotted, our tubes can be customized to meet specific filtration needs.

Wire Diameter

Perforated tubes from Huansi Wire Mesh Products Co., Ltd. are available in a variety of wire diameters, ensuring we can meet the diverse needs of different industries and applications.

Standard Diameter Range

- 10mm: Ideal for lightweight applications where precision is crucial.

- 15mm: Suitable for medium-duty applications in both industrial and architectural settings.

- 20mm and 25mm: These diameters are versatile and widely used, offering a good balance between strength and open area.

- 30mm and 35mm: Perfect for more robust applications that require larger open areas for effective material passage.

- 50mm: This is our largest standard diameter, used in heavy-duty applications where maximum strength and durability are necessary.

Length

Standard Lengths

- 50mm: Ideal for compact applications where space is limited and precision is key.

- 100mm: Suitable for small-scale projects or internal components in machinery.

- 200mm and 500mm: These mid-range lengths are perfect for general uses across various industries, providing sufficient length without unwieldiness.

- 1200mm: Our longer standard option, ideal for extensive applications that require continuous lengths of perforated tubing, such as in structural supports or lengthy filters.

Customization Available

- Custom Lengths: Recognizing that projects can have unique demands, we offer custom length options to meet specific requirements.

HOLE PATTERNS

- Round Holes: The most common and versatile pattern, suitable for a wide range of applications, offering balanced open area and strength.

- Rectangular Holes: Ideal for specific filtration requirements, allowing for directional flow and unique aesthetic designs.

- Square Holes: Provide uniform strength and open area, used in applications requiring symmetrical designs and efficient filtration.

- Triangle Holes: Offer a unique aesthetic and are used in applications where design differentiation is key.

- Diamond Holes: Known for their aesthetic appeal and structural integrity, diamond holes are often used in architectural and decorative applications.

- Hexagonal Holes: Provide high open area and strength, commonly used in high-throughput filtration applications.

- Cross Holes: Feature a cross-shaped pattern, adding both functional and decorative value to the tubes.

- Slotted Holes: Ideal for separating and filtering elongated particles, offering directional flow characteristics.

- Custom Patterns: Perforated tubes can also be customized with unique patterns based on specific drawings or application requirements, ensuring versatility and personalized solutions for diverse projects.

Applications

- Industrial and Automotive: Essential in the exhaust industry for diffusing gases effectively.

- Filtration: Utilized for the filtration of water, oil, and gases, ensuring purity and safety in processing.

- Aerospace: Critical in various aerospace applications, where precision and reliability are paramount.

- Defense: Employed in defense equipment for structural integrity and functionality.

- Food and Pharmaceutical: Key in the food and pharmaceutical industries for processing and ensuring product integrity.

- Chemical Processing: Integral in chemical manufacturing, where robust and corrosion-resistant materials are needed.

- Environmental Science: Used in environmental applications, aiding in pollution control and other ecological protection measures.