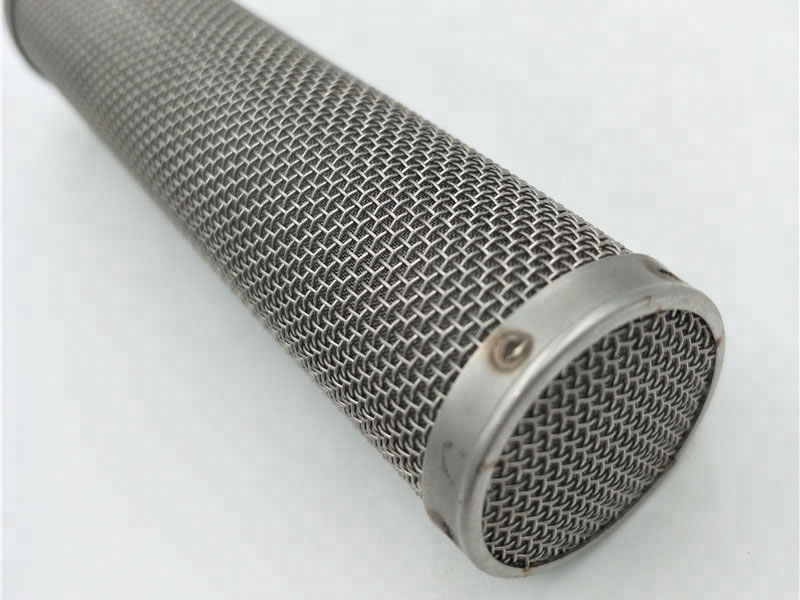

The filter tube, also known as a metal filter mesh tube, is made by welding stainless steel or iron mesh and plates using single-layer or multi-layer techniques. These tubes incorporate various materials like stainless steel woven mesh, sintered mesh, and perforated metal. They are customized to specific micron sizes, such as 25micron, 50micron, 100micron, or as per customer requirements, and their sizes and shapes are adjusted according to specific applications. Filter tubes find extensive use in water, food, and oil filtration due to their versatility and effectiveness in capturing impurities.

Specifications

Materials

- Stainless Steel Woven Mesh: Known for its strength and resistance to corrosion, stainless steel woven mesh is ideal for precise filtration applications. It ensures durability and resistance to environmental impacts, making it suitable for critical fluid handling processes.

- Sintered Mesh: This material is composed of multiple layers of stainless steel mesh that are sintered together to form a robust structure. Sintered mesh is excellent for high-pressure, high-strength applications where excellent filtration efficiency is required.

- Perforated Metal: Often chosen for its structural strength and versatility, perforated metal can be used in filter tubes that require larger open areas. It provides good mechanical strength along with adequate filtration capabilities.

Common Sizes

- Diameter Range: Customizable from 10mm to 300mm, accommodating the specific requirements of different filtration systems.

- Length Range: Typically from 100mm to 1500mm, designed to fit various equipment sizes and processing capacities in different industries.

Micron Size

- 25 Micron: Ideal for fine filtration, these tubes are suitable for applications requiring high precision to capture very small particles.

- 50 Micron: A versatile option that balances flow rate with filtration capability, perfect for moderate filtration needs.

- 100 Micron: Designed for applications where less fine filtration is sufficient, but reliability is still critical.

Custom Micron Sizes In addition to standard micron sizes, we offer customization to meet unique filtration requirements. Custom micron sizes are available to ensure that our filter tubes perfectly match the specific needs of each application, from industrial processing to specialized manufacturing.

Features

- Concentricity: They exhibit a high concentricity rate, ensuring uniformity and stability in filtration performance.

- Pressure Resistance: Designed to withstand high pressures, these tubes offer reliable performance in applications requiring robust filtration capabilities.

- Smooth Finish: With no burrs present, these filter tubes ensure smooth operation and reduce the risk of damage to the filtration system.

- Versatility: Their versatility makes them suitable for a wide range of applications, from industrial filtration to food and beverage processing.

Applications

- Petroleum and Chemical Industry: Filter tubes are crucial for filtering impurities in chemical processing and petroleum products, ensuring purity and preventing contaminants from affecting production processes.

- Oil Field Pipeline Filter: Used in oil field pipelines to filter out sediment and other particulates, ensuring the efficient and safe transport of crude oil.

- Fuel Refueling Equipment Filter: Essential in the filtration systems of fuel refueling equipment to prevent contamination of fuel, which can cause damage and inefficiency in fuel systems.

- Water Treatment Equipment Filter: Deployed in water treatment facilities to remove particles and contaminants from water, essential for achieving the required water purity standards.

- Pharmaceuticals: In the pharmaceutical industry, filter tubes are used to ensure the sterility and purity of products, crucial for maintaining health and safety standards.

- Food Processing: Filter tubes play a vital role in the food processing industry, where they are used to remove impurities from food products, ensuring safety and quality.