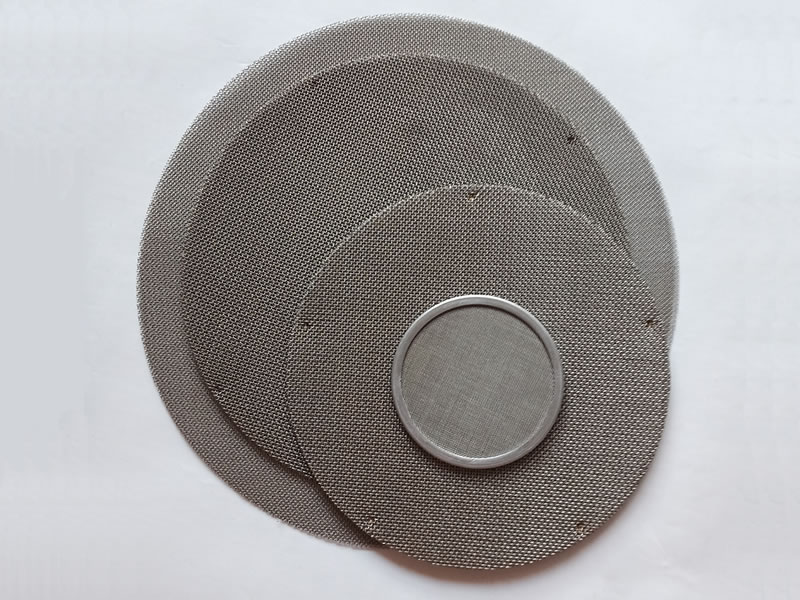

Filter mesh discs are expertly engineered to meet strict filtration requirements, essential for removing particulates from fluids and gases. These discs are widely used in several industries, including chemical processing, pharmaceutical manufacturing, and water purification. The precision engineering of these discs ensures effective contaminant removal, maintaining the purity of substances in vital industrial applications. Our range includes a variety of types and specifications, designed to cater to all aspects of filtration needs.

Materials

- Stainless Steel: Widely used for its corrosion resistance and durability, available in 304 and 316 grades. Suitable for pharmaceutical and food processing industries.

- Plain Steel: Cost-effective and strong, used for general filtration applications, particularly where corrosion resistance is not critical.

- Galvanized Steel: Enhanced with a zinc coating for better corrosion resistance, ideal for outdoor or moist environments like water treatment systems.

- Copper: Features antimicrobial properties and high thermal conductivity, commonly used in distillation processes and HVAC systems.

- Brass: A mix of copper and zinc, offering good corrosion resistance and malleability, frequently used in marine and plumbing applications.

- Phosphor Bronze: Known for excellent fatigue resistance, wear resistance, and chemical stability, suitable for heavy-duty industrial uses.

- Special Alloys: Includes materials like Monel, Inconel, and Hastelloy, designed for extreme conditions in high-pressure, corrosive, or high-temperature environments.

Filtration Grades

Filter discs are available in a comprehensive range of filtration grades to accommodate diverse industrial requirements. The grades span from ultra-fine to coarse filtration, with options beginning at 3 micrometers (μm) and extending up to 10 millimeters (mm). This spectrum ensures precise contaminant removal and process optimization across various applications.

- Ultra-Fine Filtration: Starting at 3 μm, these filter discs are ideal for critical applications in pharmaceuticals, biotechnology, and electronics manufacturing, where even the smallest particulate removal is crucial.

- Fine Filtration: Available in grades such as 10 μm, 25 μm, and 50 μm, fine filtration discs are suited for applications in chemical processing and water treatment, where finer impurities need to be separated.

- Medium Filtration: Discs in the medium range, such as 100 μm, 250 μm, and 500 μm, are typically used in food and beverage production, as well as in automotive and industrial manufacturing processes.

- Coarse Filtration: With sizes like 1 mm, 5 mm, and 10 mm, these discs are used for larger scale separations such as in pulp and paper production, large-scale wastewater treatment, and other heavy industrial applications where larger particles are filtered out.

Additional Features

Upon request, all filter discs can be ultrasonically cleaned to ensure they are free from any contaminants and residues, thereby enhancing their performance and durability. This cleaning is especially useful for applications that demand high purity levels.

Weave Styles

Filter discs come in a variety of weave styles tailored to enhance filtration performance for different applications:

- Plain Weave: The most straightforward and commonly used style, where warp and weft wires cross alternately. It provides stable and consistent pore sizes, suitable for general filtration needs.

- Twill Weave: Available upon request, this weave allows for a denser mesh with finer filtration capabilities. In twill weave, warp and weft wires cross over two and under one wire, creating a diagonal pattern that offers enhanced particle retention.

- Single-Strand Weave: Utilizes a single continuous wire for uniform mesh openings, ideal for precise filtration where consistency is paramount.

- Multi-Strand Weave: Combines multiple wires to form a single weave, increasing the mesh’s thickness and durability. This style is well-suited for more robust filtration applications requiring higher strength and resistance to pressure.

These different weave styles provide options for various industrial filtration applications, ensuring optimal performance based on specific requirements.

Structure

Filter discs are available in various structural configurations to suit different filtration needs:

- Single-Layer Network: Comprises a single mesh layer, ideal for straightforward filtration tasks where basic particle separation is required. It offers ease of maintenance and good permeability.

- Multi-Layer Film Filter: Features several layers of mesh stacked and bonded together, enhancing both filtration efficiency and durability. This structure is suited for applications needing to capture finer particles, providing more thorough filtration.

- Combined Filter Film: Integrates various materials and weave styles into one composite disc. This design is customized for complex filtration challenges that demand specific properties like chemical resistance or thermal stability.

Applications

Filter discs are employed across various industries, each benefiting from specific filtration capabilities:

- Petroleum: Used in oil and gas production to remove impurities from crude and refined products, enhancing quality and protecting equipment.

- Chemical: Essential for purifying chemicals and protecting processes from contaminants that can affect product purity and safety.

- Plastic and Chemical Fiber: Helps filter out particulates during the production of plastics and synthetic fibers, ensuring product quality and consistency.

- Food Industry: Utilized in food processing to remove unwanted particles, ensuring products meet health standards and maintain quality.

- Pharmacy: Critical in the pharmaceutical industry for filtering raw materials and products to achieve the required cleanliness and prevent contamination.

- Hydraulic Systems: Used in hydraulics to filter out debris that could cause wear or damage, ensuring system efficiency and longevity.