Expanded metal is produced in an expanding press where the basic metal is simultaneously slit and cold-formed, expanding the slits into various shapes like squares, diamonds, hexagons, and other decorative patterns. This process involves shearing a metal plate so that it stretches, creating diamond-shaped voids surrounded by interlinked bars of metal. The most common manufacturing method involves both slitting and stretching the metal in a single motion.

Specifications

Expanded metal is manufactured with specific characteristics that define its application and functionality in various industries.

- Long Way Opening (LWO)

The LWO ranges from 4mm to 100mm. This measurement is crucial as it dictates the transparency and pattern design of the mesh, affecting how it is used in architectural and functional applications. - Short Way Opening (SWO)

The SWO varies between 2mm and 40mm. This dimension determines the closeness of the mesh strands, impacting both the design and the physical properties of the expanded metal. - Strand Width

Strand widths range from 0.5mm to 8mm. This specification is essential for determining the mesh’s strength and visual appearance, playing a significant role in its structural integrity. - Thickness

Material thickness in expanded metal varies from 0.3mm to 12mm. Different thicknesses cater to varying load-bearing requirements, making the metal suitable for a wide range of structural applications. - Surface Finish

Expanded metal can be finished with anodizing, powder coating, or galvanizing. These finishes enhance both the durability against environmental factors and the aesthetic appeal of the metal. - Long Way of Diamond (LWD)

The LWD ranges from 12mm to 200mm, measuring the diagonal distance between points in the diamond-shaped openings. This dimension is crucial for the overall appearance and structural strength of the mesh. - Overall Thickness

Including the raised strands, the overall thickness ranges from 0.5mm to 40mm. This adds a three-dimensional effect to the mesh, enhancing its visual and functional properties. - Open Area

The open area percentage ranges from 20% to 80%. This specifies the proportion of open space within the mesh, allowing for varying degrees of light penetration and airflow, essential for applications requiring ventilation. - Weight

The weight of expanded metal typically ranges from 2kg/m2 to 10kg/m2, depending on the material and its specifications. The weight is an important factor for considering its use in architectural designs and support structures.

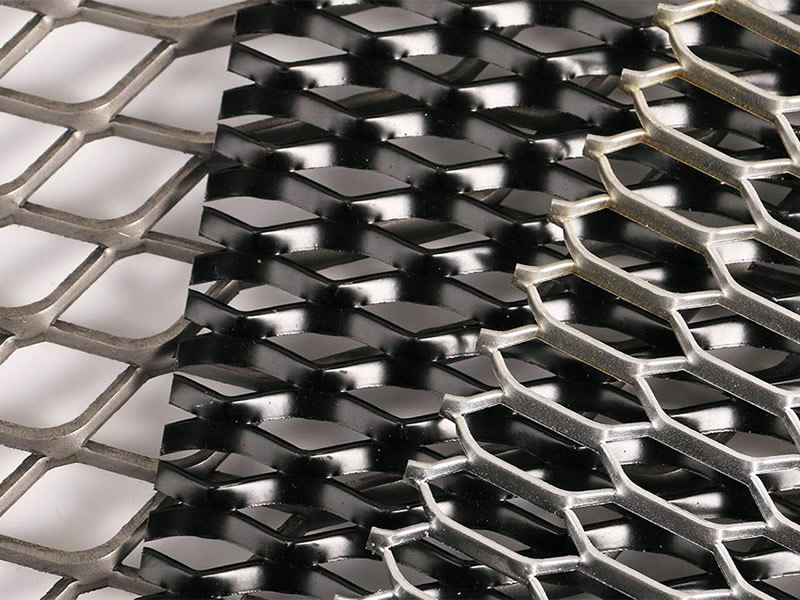

Hole Patterns

Expanded metal comes in a variety of hole patterns, each designed for specific uses and aesthetic preferences.

- Diamond Pattern: The most common pattern, featuring diamond-shaped openings that provide durability and good weight distribution, making it suitable for walkways, fences, and grilles.

- Fan-Shaped Pattern: This pattern has flared openings that resemble a fan, adding a decorative touch that’s ideal for architectural details and ornamental applications.

- Round Hole Pattern: Characterized by circular openings, this pattern allows for high airflow and light passage, perfect for ventilation panels and various filters.

- Gothic Pattern: Features arch-like openings that offer both structural strength and visual appeal, commonly used in decorative applications and architectural accents.

- Hexagonal Pattern: Consists of six-sided openings, providing more open space and enhancing airflow, often used in outdoor furniture and fencing.

- Geopattern Pattern: Incorporates various geometric shapes, offering a modern look for architectural features both indoors and out.

Materials

Expanded metal is fabricated from various metal types, each chosen for specific properties and application needs.

Carbon Steel Expanded Metal

- Hot-Rolled Carbon Steel: Used for its strength and durability, suitable for heavy-load applications.

- Cold-Rolled Carbon Steel: Preferred for finer finishes and more precise dimensions, ideal for aesthetic uses.

Stainless Steel Expanded Metal

- AISI 302, 304, 304L, 304H, 310, 316, 316L, 430: These stainless steel grades are selected for their corrosion resistance and specific properties like heat resistance (AISI 310) and low carbon content (AISI 316L). They are used in environments ranging from architectural to marine applications.

Aluminum Expanded Metal

- Aluminum Grades 1060, 3003, 5050, 1100, 1145, 1070, 5052, 6061-T6, 7075, 8011: Aluminum is lightweight and rust-resistant, making it suitable for decorative and structural applications. The specific grades offer variations in strength, formability, and corrosion resistance, accommodating everything from architectural features to structural supports.

Galvanized Steel Expanded Metal

- Galvanized Steel: Carbon steel coated with zinc to enhance corrosion resistance, suitable for outdoor environments.

Copper Expanded Metal

- Copper: Excellent for conductivity and natural corrosion resistance, often used in decorative and electrical applications.

Nickel Expanded Metal

- Nickel: Durable and excellent at resisting corrosion in extreme conditions, used in specialized industrial applications.

Titanium Expanded Metal

- Titanium: Offers high strength and exceptional corrosion resistance, preferred in aerospace and medical industries.

Other Alloys Expanded Metal

- Other Alloys: Includes various specialized metals like Inconel and Monel, chosen for specific industrial applications requiring unique properties.

Features

Expanded metal is renowned for its unique blend of strength, versatility, and efficiency, making it ideal for a wide range of applications.

- High Strength-to-Weight Ratio: Expanded metal is strong yet lightweight, supporting heavy loads without adding significant weight, perfect for structural applications where weight is a concern.

- Wear Resistance: Its one-piece construction means it doesn’t unravel, making it durable and suitable for high-impact and high-traffic areas.

- Flexible Applications: It can be used in everything from industrial platforms to architectural details, easily tailored to specific needs due to its malleable nature.

- Air and Light Flow: The open mesh design allows for excellent ventilation and light passage, ideal for screens and fencing that require airflow.

- Decorative Patterns and Finishes: Available in a variety of patterns and can be finished with coatings such as paint or galvanization, enhancing its aesthetic appeal and corrosion resistance.

- Effective Barrier: Provides a robust and secure barrier, difficult to breach, commonly used for security fences and screens.

- Economical Production: The stretching process reduces waste and manufacturing costs, making expanded metal a cost-efficient material choice

Applications